Over the past decade, at-home skate sharpening has seen significant advancements, with improved user safety being a major enhancement. The ability for consumers to safely sharpen their skates at home has greatly contributed to the growth of this product category.

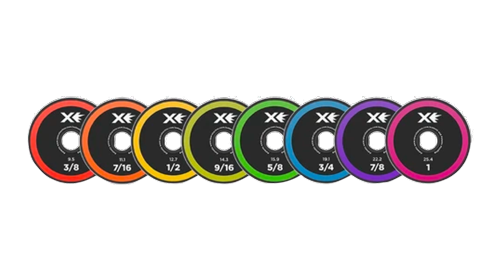

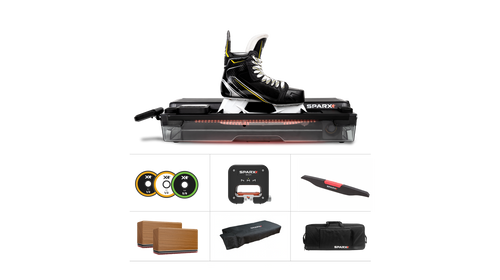

The Sparx Sharpener 3, although it may seem like an obvious design today (Figure 1), required extensive thought and engineering. A look back at the history of at-home skate sharpening reveals a much different origin of at-home skate sharpening.

Figure 1 - The Sparx Sharpener 3

Figure 1 - The Sparx Sharpener 3

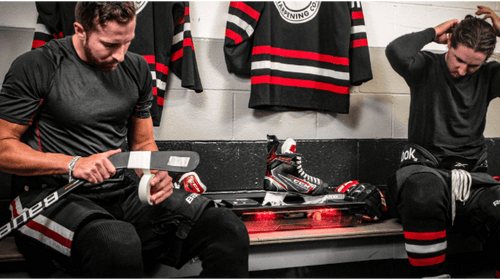

Safety is another major issue with bench-grinder style home sharpeners. The exposed, fast-spinning mechanical components and the sparks generated during sharpening (Figure 3) could easily compromise safety even with the use of personal protective equipment (PPE). Additionally, the dust generated during the sharpening process poses another safety concern.

The presence of sharpening dust, technically called swarf, can be observed in any hockey shop using a manual skate sharpener. A look around the sharpening area will reveal a significant amount of fine dust collected on tables, floors, and walls. This fine dust, a mixture of abrasive and metallic material, ranges from 2 to 200 microns (µm) in diameter. Without proper management, this dust can become airborne and pose health risks. The finest particles in swarf, those less than 2.5 microns in diameter (known as PM2.5 or fine particles), are particularly hazardous as they are the most likely to become airborne.

Figure 3 - Sparks Generate During Traditional Skate Sharpening

Figure 3 - Sparks Generate During Traditional Skate Sharpening

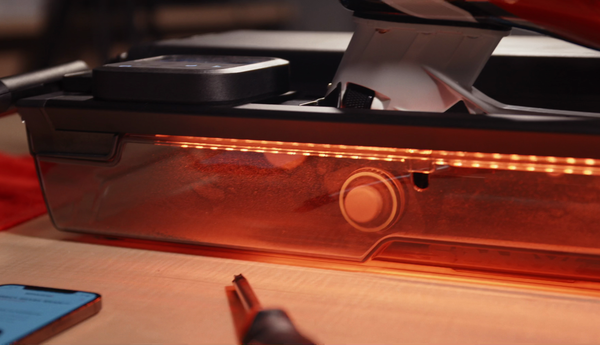

When Sparx Hockey embarked on the creation of the world's most accurate and user-friendly home sharpener in 2014, safety was our top concern. Sparx engineers designed the sharpener to shield all moving mechanical components, and the design team focused on capturing as much dust as possible generated by the sharpening process. By incorporating adjustable slot covers that are user-adjustable to seal against different sized skates and including a HEPA-rated air filter in the sharpener's dust handling system, the Sparx Sharpener is designed to capture airborne particulate and contain it within the sharpener enclosure.* HEPA, which stands for High Efficiency Particulate Air, is a globally recognized air filter efficiency standard.

The HEPA filter material integrated into the Sparx Sharpener 3 (Figure 4) is specified at H13 grade according to the ISO standard, measures 140 x 70mm and consists of two layers of filter material folded into 38 pleats, providing a total of 110,000 mm² of active filter area. This filter removes 99.97% of airborne particles that are 0.3 microns (µm) or larger.

Figure 4 - The HEPA-rated filter integrated into the Sparx Sharpener

Extensive testing of the Sparx Hockey air filter's efficacy demonstrates that it blocks dust particles with diameters approximately 10 times smaller than the smallest particles generated during the sharpening process. Notably, the sharpening process produces dust particles smaller than 10 microns in diameter, which must be addressed due to the health concerns associated with airborne fine particulate matter.

While it might seem obvious that any at-home skate sharpening machine would include a dust handling system, the Sparx Sharpener is currently the only automated at-home sharpening system in the world equipped with this feature. Competing at-home sharpeners either lack a dust collection solution entirely or suggest that users connect their own vacuum to an external port on the unit's side.

Unfortunately, many users connect consumer-grade wet/dry vacuums equipped with standard filters (Figure 5), which are not designed to protect against the fine dust particles generated during the sharpening process. For instance, a standard vacuum filter (non-HEPA) removes 99% of particles up to 3 microns and only 80% of particles down to 0.3 microns. This is significantly less effective than a HEPA filter, which captures 99.97% of particles that are 0.3 microns or larger. Given that a substantial amount of sharpening dust is smaller than 10 microns, relying on standard vacuum filters is inadequate.

Figure 5 - Consumer Grade Shop Vacuum with Standard Filter

When purchasing an at-home automated sharpener, it is essential to choose systems that manage the dust produced by the sharpening process. Due to the nature and size of the generated dust, using an integrated dust management system specifically designed for this purpose is critical, rather than attaching a sharpener to a vacuum that was not designed for this task.

From the original, first generation Sparx Sharpener to the recently released Sparx Sharpener 3, every Sparx Sharpener has included an integrated dust handling system to ensure a safe and clean sharpening environment.

*Always refer to the Sparx Hockey operating manual for your sharpener to follow the complete safety and usage instructions. Manuals can be found here.