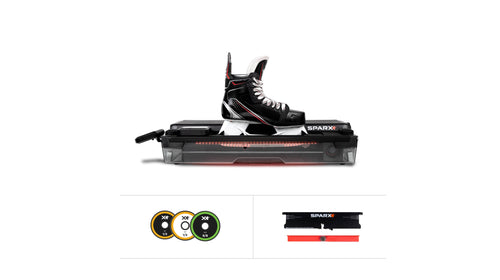

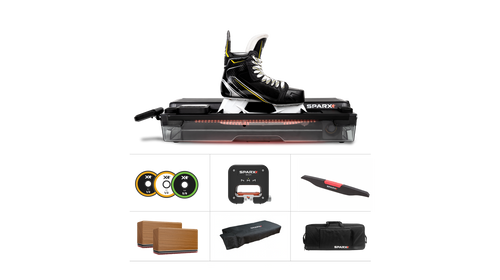

The Heart of the Sparx Sharpening Ecosystem

SKATE SHARPENING BASICS

Skate Sharpening can easily be defined as the process of shaping the blade of an ice skate with a grinding machine to create two edges that are sharp, smooth and level. When an ice skate is used on the ice, the blade can become dull or lose its edge, which can negatively affect the skater’s performance and increase the risk of injury.

EVEN, SHARP, SMOOTH

The elements of a good sharpening can be summarized with the abbreviation ESS. ESS stands for Even, Sharp and Smooth. A properly sharpened skate should have Even Edges, Sharp Edges and a Smooth Surface Finish. It is important to check these three elements any time your skates are sharpened. Even if only one of these elements is off, your performance could be impacted.

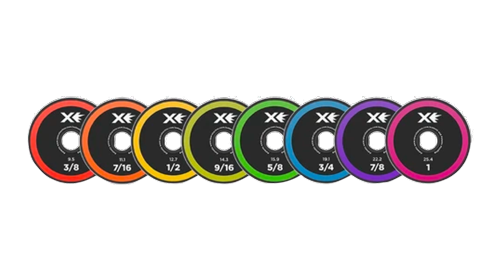

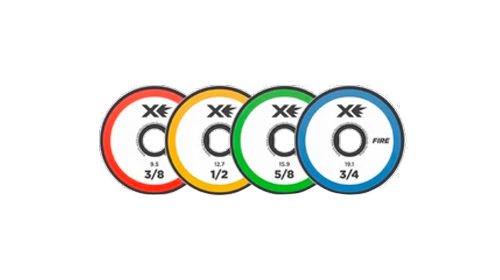

RADIUS OF HOLLOW

One of the most confusing aspects of skate sharpening for most individuals is the term Radius of Hollow. While there is some basic math involved, the concept of Radius of Hollow (or hollow or RoH for short) is quite simple. A radius is the distance from the center of a circle to its outer edge and a hollow is a cut or depression in something.

BLADE PROFILE

There is often confusion between the Radius of Hollow of a skate blade and the profile (also known as the ‘rocker’ or ‘contour’). This confusion is understandable because both terms use the radius of a circle as their measurement. When referring to the Radius of Hollow (the depth of the cut in the blade), the measurement is in inches. When referring to the profile of the skate blade, the measurement is in feet.

DEBURRING

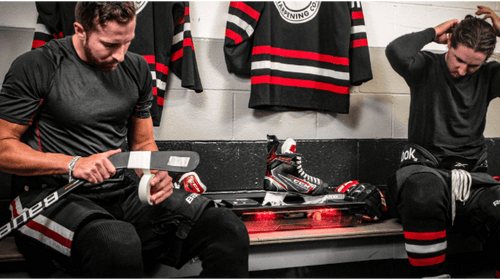

After every skate sharpening and before testing the edges, we recommend deburring both sides of the blade with a deburring stone, rubber stone or leather strop. In any sharpening (manual or automated), when the stone cuts the steel, it is cutting out the desired hollow and often this cut will leave behind steel that has “folded over” the sides of the blade.

TESTING BLADE EDGES

Once you have sharpened your skates and completed the deburring process, it is always a good idea to check your edges to make sure they are even. Below are few different ways to measure your edges.